Chinese Journal of Tissue Engineering Research ›› 2017, Vol. 21 ›› Issue (2): 273-279.doi: 10.3969/j.issn.2095-4344.2017.02.020

Previous Articles Next Articles

Controlled release of porous calcium phosphate nanoparticles loaded with vitamin C

- 1Tongde Hospital of Zhejiang Province, Hangzhou 310012, Zhejiang Province, China; 2Zhejiang Academy of Traditional Chinese Medicine, Hangzhou 310007, Zhejiang Province, China

-

Received:2016-10-29Online:2017-01-18Published:2017-02-27 -

Contact:Zhu Yong-qiang, Associate researcher, Zhejiang Academy of Traditional Chinese Medicine, Hangzhou 310007, Zhejiang Province, China -

About author:Kong Jun, Master, Associate chief physician, Tongde Hospital of Zhejiang Province, Hangzhou 310012, Zhejiang Province, China

CLC Number:

Cite this article

Kong Jun, Zhu Yong-qiang.

share this article

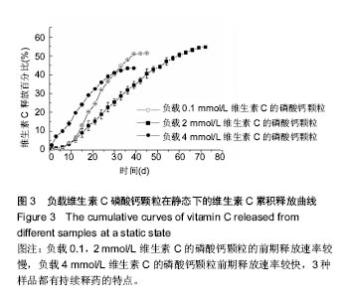

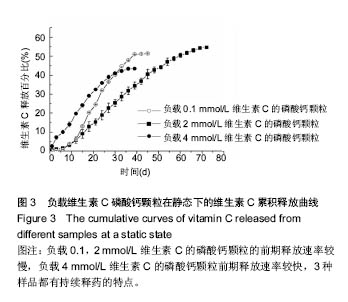

2.3 比表面积和孔径分布检测结果 样品的比表面对药物负载和释放都有一定的影响,对样品的比表面积和孔径分布进行了测试,结果发现:0.1VC-CPSs和CPSs颗粒具有较发达的中孔(2-50 nm)和大孔,比表面积为 83.35 m2/g;2VC-CPSs颗粒的孔尺寸约为11 nm,具有大量的微孔,所以该样品比表面积较大,为95.87 m2/g;4VC-CPSs颗粒的比表面积最小,为77.64 m2/g,这可能是由于4VC-CPSs颗粒尺寸较大,而却只有少量微孔和较多大孔所导致;CPSs颗粒具有较多平均尺寸约为13 nm的微 孔,比表面积为89.82 m2/g。通常情况下,载体的比表面越大负载的药物量越多。 2.4 载药量检测结果 利用差重法检测了3种颗粒上所负载的维生素C量,其中2VC-CPSs样品具有较高的载药量,负载率高达(87.2±1.2)%;0.1VC-CPSs样品的维生素C负载率小于2VC-CPSs,为(59.9±5.4)%;4VC-CPSs样品负载率最低,为(28.4±26.3)%。药物负载率不仅与颗粒对维生素C的吸附量有关,还与颗粒表面和内部的孔结构有较大的关系。2VC-CPSs具有较发达的微孔,比表面积大,这种结构适合于包载和吸附维生素C。而0.1VC-CPSs样品具有较多中孔和大孔,比表面积小,表面吸附的药量也较少。4VC-CPSs样品表面大孔明显,比表面积最小,载药率不足。因此3种样品中,2VC-CPSs样品具有最高的载药量。 2.5 磷酸钙对维生素C控释的能力结果 如图3所示,0.1VC-CPSs和2VC-CPSs的前期释放速率较慢, 4VC-CPSs前期释放速率较快,3种样品都有持续释药的特点。药物释放前12 d内,0.1VC-CPSs样品的释药速率为2.597 μg/d,随后的27 d内,速率增加到8.82 μg/d,之后释药速率急剧减少至0.44 μg/d;而2VC-CPSs样品前12 d的释药速率为74.4 μg/d,随后的45 d内药物较稳定地从载体中释放出来,其释药速率为147 μg/d,近2个月后速率减小为60.57 μg/d;4VC-CPSs样品释药前期没有出现较慢释放的现象,而是以约127.9 μg/d的释药速率持续释放了33 d,随后速率降为21 μg/d。所得到的磷酸钙颗粒对维生素C具有持久的控释能力,可能是由于维生素C与磷酸钙的羟基之间生成了氢键。但3种颗粒的药物释放率较低,均在55%以下,这可能是由于释药过程在常温常压环境中进行,对负载的维生素C的稳定性产生了影响,部分维生素C被氧化失效所导致。 "

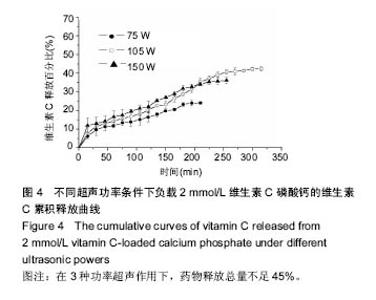

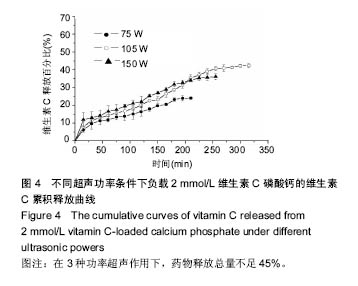

2.6 超声处理下磷酸钙对维生素C控释的能力 以具有最高药物负载率的2VC-CPSs样品为载体模型,探索了超声处理对药物释放的影响。由图4可知维生素C存在一定的突释现象,第1次释放量为5%-15%,而随后的释放速度较缓慢。在75,105,150 W超声辅助条件下,分别持续释放了220,340,260 min。计算可知,当超声功率为75 W时,药物平均释放速度约为16.36 μg/min,约180 min后,药物平均释放速度急剧减小为约7.7 μg/min;当超声功率增加至105 W时,药物平均释放速度增大到22.46 μg/min,持续释放了240 min后才减小为约4.62 μg/min;当超声功率为150 W时,由于首次突释较多,其药物稳定释放平均速度反而减小到了 17.11 μg/min,且在250 min时释放速度就急剧减小。在3种功率超声作用下,药物释放总量不足45%。"

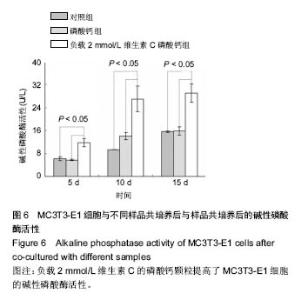

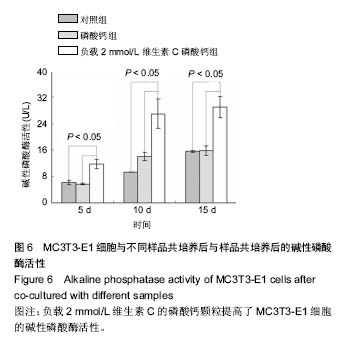

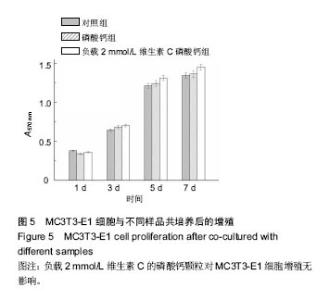

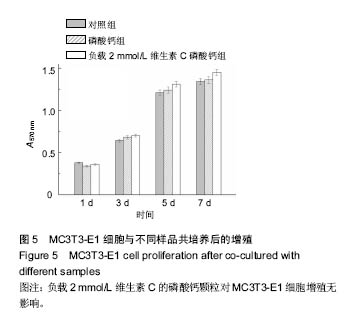

2.7 载药磷酸钙对细胞增殖与分化的影响结果 在与样品共培养不同时间后,细胞的增殖情况见图5所示。共培养1 d后,CPSs和2VC-CPSs样品中的细胞数量与空白对照组基本相同;随着共培养时间的延长,样品组中的细胞数量明显增多,但与对照组相比没有明显差异,说明样品对细胞的增殖没有明显负面影响,具有良好的细胞相容性。 与样品共培养一定时间后,对细胞的碱性磷酸酶活性进行了测定,结果见图6所示。碱性磷酸酶检测结果表明2VC-CPSs样品与对照组间均有显著性差异(P < 0.05),载有维生素C的磷酸钙培养的细胞碱性磷酸酶活性比纯磷酸钙有明显提高,而纯磷酸钙与纯血清培养的细胞碱性磷酸酶活性差异不明显。这表明载有维生素C的磷酸钙材料提高了成骨细胞的分化,而且这种促进作用随着共培养时间的延长而增大。该结果充分证明了维生素C在载体材料中的药物活性被较好的保存下来[16-17]。"

| [1]Shen Y,Jin E,Zhang B,et al. Prodrug lipid forming high drug loading multifunctional nanocapsules for cancer intracellular drug delivery.J Am Chem Soc. 2010;132: 4259-4265.[2]林山,黄晓梅,芮钢,等.数字化珊瑚羟基磷灰石人工骨支架的体外降解性能[J].中国组织工程研究, 2016,20(3):330-335.[3]高昊辰,汪沛,曹志中,等.载米诺环素纳米羟基磷灰石/壳聚糖复合体的体外释放及抑菌性[J].中国组织工程研究, 2016,20(8): 1118-1125.[4]强巴单增,刘晓兰.多孔纳米羟基磷灰石/聚酰胺复合骨修复材料的制备[J].中国组织工程研究, 2016,20(3):392-396.[5]Ginebra M,Traykova T,Planell J.Calcium phosphate cements as bone drug delivery systems: a review.J Control Release. 2006;113:102-110.[6]Xu H,Weir M,Burguera E,et al.Injectable and macroporous calcium phosphate cement scaffold.Biomaterials. 2006; 27: 4279-4287.[7]Ginebra M,Traykova T,Planell J.Calcium phosphate cements: competitive drug carriers for the musculoskeletal system? Biomaterials. 2006;27:2171-2177.[8]Sugiyama T,Akiyama S,Ikoma T.Calcium phosphate with high specific surface area synthesized by a reverse micro-emulsion method.MRS Adv. 2016;1(11):723-728.[9]Desai K,Liu C,Park H.Characteristics of vitamin C encapsulated tripolyphosphate-chitosan microspheres as affected by chitosan molecular weight.J Microencapsulation. 2006;23(1):79-90.[10]Halliwell B.Vitamin C and genomic stability. Mutat Res-Fund Mol M.2001;475:29-35.[11]路继业,王岩,蔡胥.骨髓基质干细胞成骨的研究进展[J].中华创伤骨科杂志,2004,6(5):578-580.[12]Yang W, Deng C, Liu P, et al. Sustained release of aspirin and vitamin C from titanium nanotubes: An experimental and stimulation study.Maters Sci Eng C.2016;64(1):139-147.[13]Esposito E,Cervellati F,Menegatti E,et al.Spray dried Eudragitmicroparticles as encapsulation devices for vitamin C.Int J Pharm.2002;242:329-334.[14]Lin F,Li Y,Jin J,et al.Deposition behavior and properties of silk fibroin scaffolds soaked in simulated body fluid.Mater Chem Phys.2008;111:92-97.[15]Kim H, GuH,Lee H.Microspheres of Collagen-Apatite Nanocomposites with Osteogenic Potential for Tissue Engineering.Tissue Eng.2007;13:965-973.[16]May JM,Qu ZC.Transport and intracellular accumulation of vitamin C in endothelial cells: relevance to collagen synthesis.Arch BiochemBiophys. 2005;434:178-186.[17]Boskey A,Stiner D,Doty SB,et al.Requirement of vitamin C for cartilage calcification in a differentiating chick limb-bud mesenchymal cell culture.Bone.1991; 12(4):277-282.[18]Pizzoccaro M,Nikel O,Sene S,et al.Adsorption of benzoxaboroles on hydroxyapatite phases.Acta BIomaterialia. 2016;41:342-350.[19]Li H,Jiang F,Ye S,et al.Bioactive apatite incorporated alginate microspheres with sustained drug-delivery for bone regeneration application.Maters Sci Eng C. 2016;62: 779-786.[20]Xiao W,Fu H,Rahaman MN,et al.Hollow hydroxyapatite microspheres: A novel bioactive and osteoconductive carrier for controlled release of bone morphogenetic protein-2 in bone regeneration.Acta Biomaterialia. 2016;9:8374-8383.[21]Mizushima Y,Ikoma T,Tanaka J,et al.Injectable porous hydroxyapatite microparticles as a new carrier for protein and lipophilic drugs.J Control Release. 2006;110:260-265.[22]Yang P,Quan Z,Li C,et al.Bioactive, luminescent and mesoporous europium-doped hydroxyapatite as a drug carrier. Biomaterials.2008;29:4341-4347.[23]Ho ML,Fu YC,Wang GJ,et al.Controlled release carrier of BSA made by W/O/W emulsion method containing PLGA and hydroxyapatite.J Control Release. 2008;128:142-148.[24]Sunkara S,Munichandraiah N,Varma KBR,et al.A sonochemical approach for the synthesis of thermally stable mesoporous microspheres of TiO2 for use as high performance anodes for Li-ion batteries.New J Chem.2016;40: 7197-7203.[25]Nostro PL,Ramsch R,Fratini E,et al.Organogels from a vitamin C-based surfactant. J Phy Chem B. 2007;111: 11714-11721.[26]Figueroa-Mendez R,Rivas-Arcancibia S.Vitamin C in Health and Disease: Its Role in the Metabolism of Cells and Redox State in the Brain.Front Physiol.2015, DOI:10.3389/fphys.2015.00397[27]Pham PV,Tran NY,Phan NLC,et al.Vitamin C stimulates human gingival stem cell proliferation and expression of pluripotent markers. In Vitro Cell Dev Biol Anim. 2016;52(2): 218-227.[28]Wei F,Qu C,Song T,et al.Vitamin C treatment promotes mesenchymal stem cell sheet formation and tissue regeneration by elevating telomerase activity.J Cell Physiol. 2012;227:3216-3224.[29]Franceschi RT,Iyer BS.Relationship between collagen synthesis and expression of the osteoblast phenotype in MC3T3-E1 cells.J Bone Miner Res. 1992;7(2):235-246. |

| [1] | Yao Xiaoling, Peng Jiancheng, Xu Yuerong, Yang Zhidong, Zhang Shuncong. Variable-angle zero-notch anterior interbody fusion system in the treatment of cervical spondylotic myelopathy: 30-month follow-up [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(9): 1377-1382. |

| [2] | Zhang Jinglin, Leng Min, Zhu Boheng, Wang Hong. Mechanism and application of stem cell-derived exosomes in promoting diabetic wound healing [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(7): 1113-1118. |

| [3] | An Weizheng, He Xiao, Ren Shuai, Liu Jianyu. Potential of muscle-derived stem cells in peripheral nerve regeneration [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(7): 1130-1136. |

| [4] | He Yunying, Li Lingjie, Zhang Shuqi, Li Yuzhou, Yang Sheng, Ji Ping. Method of constructing cell spheroids based on agarose and polyacrylic molds [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 553-559. |

| [5] | He Guanyu, Xu Baoshan, Du Lilong, Zhang Tongxing, Huo Zhenxin, Shen Li. Biomimetic orientated microchannel annulus fibrosus scaffold constructed by silk fibroin [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 560-566. |

| [6] | Chen Xiaoxu, Luo Yaxin, Bi Haoran, Yang Kun. Preparation and application of acellular scaffold in tissue engineering and regenerative medicine [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 591-596. |

| [7] | Kang Kunlong, Wang Xintao. Research hotspot of biological scaffold materials promoting osteogenic differentiation of bone marrow mesenchymal stem cells [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 597-603. |

| [8] | Shen Jiahua, Fu Yong. Application of graphene-based nanomaterials in stem cells [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 604-609. |

| [9] | Zhang Tong, Cai Jinchi, Yuan Zhifa, Zhao Haiyan, Han Xingwen, Wang Wenji. Hyaluronic acid-based composite hydrogel in cartilage injury caused by osteoarthritis: application and mechanism [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 617-625. |

| [10] | Li Hui, Chen Lianglong. Application and characteristics of bone graft materials in the treatment of spinal tuberculosis [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 626-630. |

| [11] | Gao Cangjian, Yang Zhen, Liu Shuyun, Li Hao, Fu Liwei, Zhao Tianyuan, Chen Wei, Liao Zhiyao, Li Pinxue, Sui Xiang, Guo Quanyi. Electrospinning for rotator cuff repair [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(4): 637-642. |

| [12] | Guan Jian, Jia Yanfei, Zhang Baoxin , Zhao Guozhong. Application of 4D bioprinting in tissue engineering [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(3): 446-455. |

| [13] | Liu Jiali, Suo Hairui, Yang Han, Wang Ling, Xu Mingen. Influence of lay-down angles on mechanical properties of three-dimensional printed polycaprolactone scaffolds [J]. Chinese Journal of Tissue Engineering Research, 2022, 10(16): 2612-2617. |

| [14] | Huang Bo, Chen Mingxue, Peng Liqing, Luo Xujiang, Li Huo, Wang Hao, Tian Qinyu, Lu Xiaobo, Liu Shuyun, Guo Quanyi . Fabrication and biocompatibility of injectable gelatin-methacryloyl/cartilage-derived matrix particles composite hydrogel scaffold [J]. Chinese Journal of Tissue Engineering Research, 2022, 10(16): 2600-2606. |

| [15] | Fang Xiaoyang, Tang Tian, Wang Nan, Qian Yuzhang, Xie Lin. Repair and regenerative therapies of the annulus fibrosus [J]. Chinese Journal of Tissue Engineering Research, 2022, 26(10): 1582-1587. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||